Top Procurement Risks And Mitigation Plan

What dangers does your supply chain face?

Here are some of the top procurement risks and action plans to mitigate them.

Price Fluctuations

Price risk means the risk of an unmanageable price increase. Many commodities, like steel, aluminum, food grains, etc., undergo price revisions from time to time.

It is the financial risk on an entity's financial performance/profitability upon fluctuations in the prices of commodities that are out of the entity's control as they are dependent on external factors, like demand-supply gap, forex changes, etc.

Fluctuations in commodity prices affect production costs, product pricing, profitability, earnings, etc.

Supply Strategies

Companies may use multiple suppliers to ensure competitive pricing and mitigate the impact of potential price increases or apply a collaborative partnership approach.

They may implement fixed-price purchase agreements or agreements with pre-agreed caps for price increases.

However, it is essential that there are at least two suppliers per commodity, and a strategic sourcing or vendor development team plays a crucial role in implementing this strategy.

Financial Hedging

An action that protects against adverse price movement to remove uncertainty. Finance plays a vital role here; however, close coordination with the supply chain team always helps finance, understand this risk and take steps.

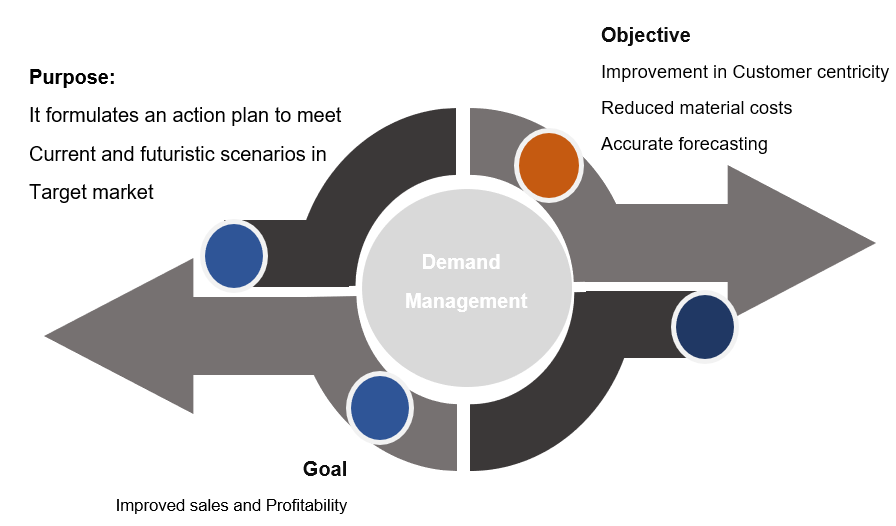

Demand Management

One of the important actions under this initiative would be to obtain the quarterly sales forecast from sales, convert it into the partwise requirement with the help of design/application engineering and take advance procurement actions.

Reconstructing product BOM and reducing the use of the commodity is an alternative means of managing adverse price effects.

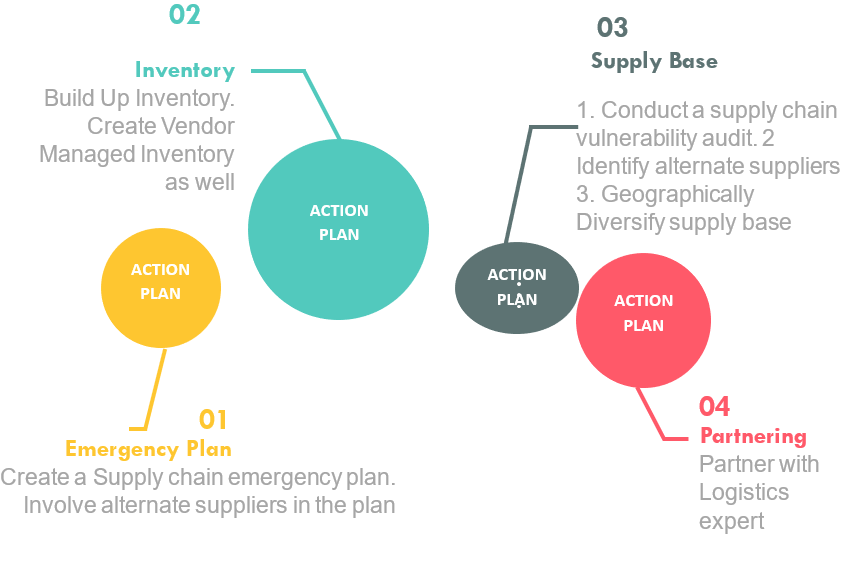

Supply Chain Disruptions

1. Pandemics

2. Natural Disasters

3. Transportation Failures and Delays

4. Cyber attacks

Inaccurate Forecasting

Three steps to mitigate the challenge

Lack of Automation

- Data is not unified, and processes are manually orchestrated

- Tools are not customized to unique business needs

- Unstructured solutions

Inaccurate Internal Need Analysis

This step aims to benchmark current performance and then identify needs and targets to develop a procurement strategy.

This involves the collection of several different types of data. The purpose of collecting initial data is to benchmark current performance, resources used, costs for all the departments/functions in the organization, and current growth projections.

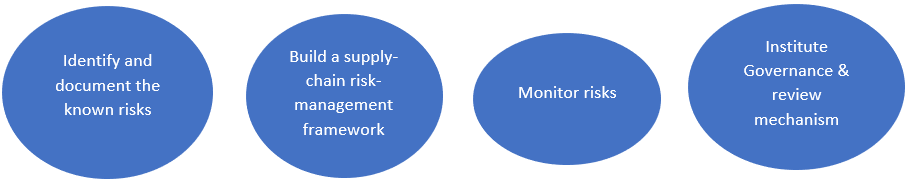

How to mitigate no supply chain risk management

This article was contributed by our expert Manoj Yermalkar

Frequently Asked Questions Answered by Manoj Yermalkar

Q1. How do you identify risks in procurement?

By value stream mapping the entire procurement chain and also creating end-to-end visibility, we can systematically identify risks in procurement.

Q2. How do you prevent price instability?

By taking multiple steps like demand management, advance procurement actions, creating vendor-managed inventory, and financial hedging.

Q3. What are the constraints in a needs analysis?

- Unavailability of required data

- Unavailability of a proper scope

- Lack of understanding of the perceived and expressed need.

Q4. What are the three basic elements of an automated system?

In the context of an automated procurement system, the basic elements are as below :

- Drive to accomplish the process

- Process/standard operating procedure

- Controls

Comments

No comments yet. Be the first to comment!