Significance Of Graphite In The Die Mold Industry

The die and mold industry has become crucial to the country’s manufacturing sector. The demand for precision tooling and molds has increased significantly with the growth of various industries like automotive, consumer goods, and electronics. Further, the government’s Make-In-India initiative encourages companies to set up or expand their manufacturing facilities in the country. This has pumped up the domestic demand for Indian die mold manufacturers.

Benefits of using Graphite

Graphite is vital in the die mold industry due to its unique properties and characteristics. It is widely used in various applications within the industry, especially in manufacturing die molds for specific processes like injection moulding, die-casting, and other applications.

Its usage enhances manufacturing processes, reduces costs, and contributes to producing high-quality, precision parts. Graphite's role in the die mold industry will likely grow, further solidifying its position as a preferred material for mould-making applications.

The types of parts machined are called Electrodes. These electrodes are used in EDM (Electric Discharge Machining) for etching out the shapes and profiles of a die or mold in steel. This steel die mold is used for the final purpose of injection moulding or die casting.

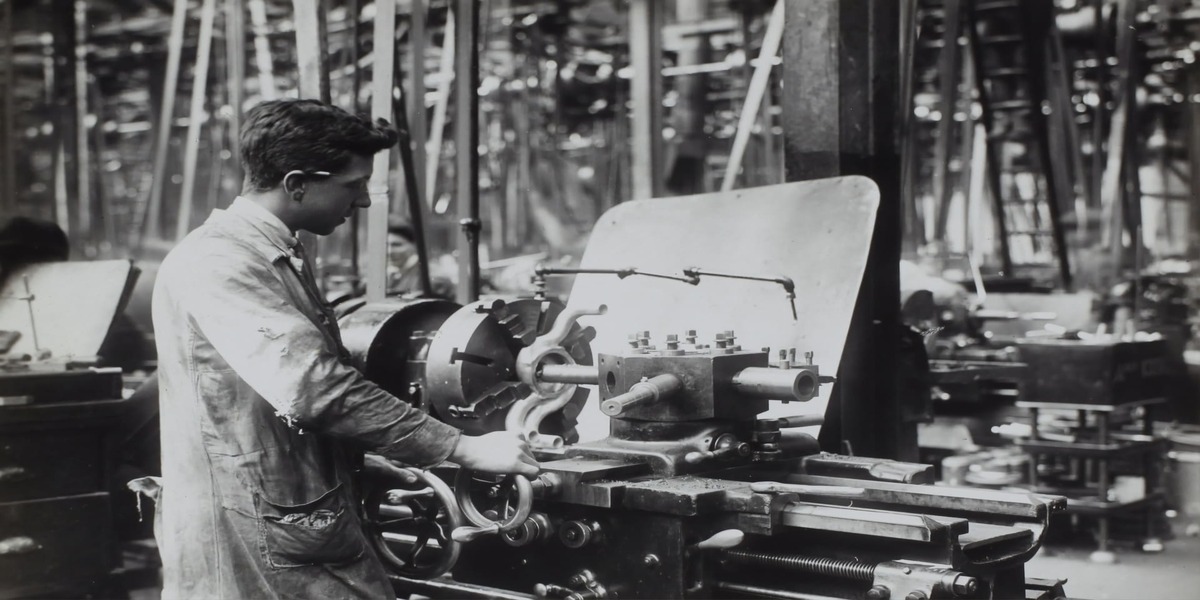

Graphite Machining

Graphite machining requires specialized machines due to graphite's unique properties, such as its high hardness and abrasive nature. The machines used for graphite machining are designed to handle these characteristics efficiently and accurately.

Computer Numerical Control Milling Machines

CNC (Computer Numerical Control) milling machines are used for graphite machining. These machines use rotary cutting tools, like endmills, drills, and face mill cutters, to remove material from a workpiece, shaping it into the desired form.

CNC milling machines equipped with high-speed spindles and advanced tooling capabilities are essential for precision graphite machining.

Vertical Machining Centre

VMCs (Vertical Machining Centre) are a type of CNC milling machine that operates vertically, allowing for three-axis or multi-axis machining. They are commonly used for graphite electrode manufacturing, where intricate details and complex geometries must be machined.

CNC Turning Centres

CNC turning centres are used for graphite machining operations that require rotational symmetry. They can turn cylindrical or conical shapes, and with the right tooling, they can handle graphite material effectively. Many of these machines have multiple spindles and can handle turning and milling operations. They are called turn-mill centres.

Wire EDM Machines

Wire EDM machines use a thin, electrically charged wire to cut through the workpiece precisely. These machines are suitable for producing thin and delicate graphite electrodes.

Diamond-coated cutting tools are used in graphite machining due to the material's abrasive nature. Additionally, custom work-holding solutions are required to hold graphite workpieces during machining.

To program and control CNC machines effectively, CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software is required. This software allows for creating complex toolpaths and ensures precise execution of machining operations. The software helps trace the tool path on the computer before the machining. This helps in making corrections in the tool path. Sometimes machining can even last more than 12 hours without interruption.

Conclusion

The graphite machining industry is both capital and skill intensive. This is also a very competitive market. The speed of delivery is crucial for a market presence. The graphite material used in electrode making is isostatic graphite. This type of graphite is not made in India, and hence imported.

Frequently Asked Questions

1. How can the use of graphite in die molds lead to cost savings and increased productivity for manufacturers?

Faster turnaround time for graphite electrodes can help reduce the same for die mold makers. Thus increasing productivity.

2. What further research and development efforts are being made to enhance graphite's role in the die mold industry?

Graphite's role in die mold making is already well established, and there is no alternative to it at the moment. Though copper is used in some cases, as graphite is much cheaper than copper, graphite is always preferred.

3. What are the key challenges and considerations when machining graphite for die and mold production?

Graphite is a delicate and breakable material. Handling of graphite should be done with care.

- Clamping should be done using appropriate holding devices. Correct spindle rpm is vital for optimum cutting efficiency

- Lower speed can lead to faster wearing out of tools

- Graphite machining is very dusty; hence a very efficient dust collection is important

4. What are the critical factors to consider when choosing the appropriate graphite material for electrode machining?

Graphite comes in different coarseness, that is, the particle size varies from grade to grade. The smaller the particle size, the denser it is. Also makes this more expensive. Depending on the intricacy of the electrode, the grade is chosen.

Comments

No comments yet. Be the first to comment!