Manufacturing’s Evolution: Industry 4.0 & Beyond

Before heavy machinery and automation, manufacturing was done manually. There was no automation or computers to handle the various stages of design, production, and quality control. It was all done by the available/skilled workforce.

The first major shift came during the First Industrial Revolution (Industry 1.0) in the 18th century, where, instead of items being produced by basic means, processes were invented, and machines produced items.

First Industrial Revolution (Industry 1.0)

The first industrial revolution marked a shift from an agrarian and handicraft economy to one dominated by machinery and significantly impacted industries like mining, textiles, glass, and agriculture.

Second Industrial Revolution (Industry 2.0)

The next shift in manufacturing is the period between 1871 and 1914, known as the Second Industrial Revolution (Industry 2.0).

The Second Industrial Revolution was a period of great economic growth, with increased productivity.

Third Industrial Revolution (Industry 3.0)

The important point of this phase is the mass production and widespread use of digital logic and computers, microprocessors, digital cellular phones, and the internet. The digital revolution converted technology from analog to digital format.

Fourth Industrial Revolution (Industry 4.0)

The Fourth industrial revolution, also known as Industry 4.0 - is a combination of physical assets and advanced digital technologies - like Internet of Things (IoT), Artificial Intelligence (AI), robots, drones, autonomous vehicles, 3D printing, cloud computing, etc.

Trends in the Manufacturing Industry

Manufacturing Trends that are changing the industry are:

Digitalization and Industry 4.0

Digitalization has profoundly impacted the manufacturing sector, enabling businesses to optimize processes, improve quality, and reduce costs. Industry 4.0 is the latest phase of the manufacturing industry’s digital transformation. It integrates advanced technologies — like the Internet of Things (IoT), Artificial Intelligence (AI), and Cloud Computing into an organization’s existing manufacturing processes.

Industry 4.0 enables manufacturers to conduct real-time data collection and analysis for vast amounts of data, providing them valuable insights into their operations.

Artificial Intelligence

One of the most significant benefits of Artificial Intelligence ( AI) in manufacturing is its ability to analyze vast amounts of data in real time. With Industrial Internet of Things (IIoT), devices and sensors collect data from machines, equipment, and production lines.

AI algorithms can quickly process and analyze data to identify patterns and trends, helping manufacturers understand how production processes are performing.

Companies can also use AI to identify anomalies and equipment defects. Machine learning algorithms, for instance, can be trained to identify patterns in the data and manage decision-making based on those patterns, allowing manufacturers to catch quality issues early in the production process.

It also helps implement predictive maintenance systems and processes, streamline supply chain management, and proactively identify and address workplace safety hazards.

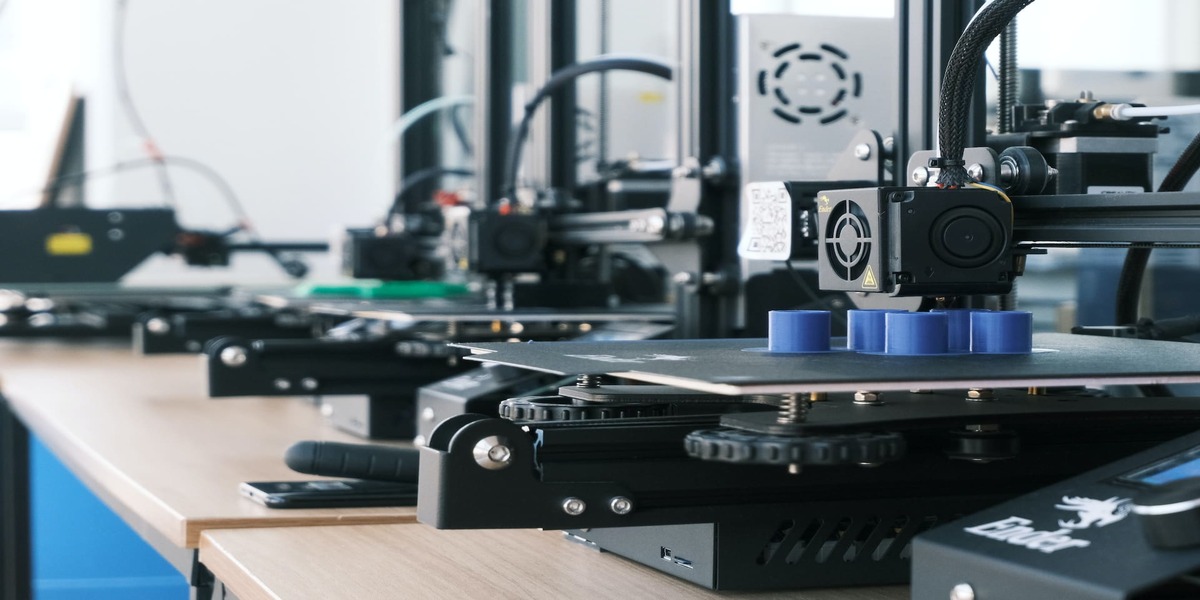

3D printing

3D printing, also known as additive manufacturing, is a rapidly growing technology that has changed how companies design, prototype, and manufacture products. In smart factories, 3D printing is a popular tool for producing complex parts and components quickly and precisely.

Traditional manufacturing processes, like injection molding, can be limited by the complexity of a prototype’s part geometry, and they may require multiple steps and operations to produce. With 3D printing, manufacturers can produce complex geometries in a single step, reducing manufacturing time and costs.

Additive manufacturing is particularly useful in aerospace, automotive, and healthcare industries, where complex parts and components are required. 3D technology helps to produce spare parts on demand, reducing the need for large inventories and improving supply chain efficiency.

Robotics and Automation

Robotics and automation have been transforming the manufacturing industry for years. Robotic Process Automation has been a key driver of smart manufacturing, with robots taking on repetitive and/or dangerous tasks like assembly, welding, and material handling.

Robots can perform repetitive tasks faster and with a much higher degree of accuracy and precision than human workers, improving product quality and reducing defects.

Manufacturers are also integrating robotics with Industrial Internet of Things (IIoT) sensors and big data analytics to create a more flexible and responsive production environment.

Some of the important benefits of Robotic Process Automation are:

- Improvement in system efficiency

- Reduce errors

- Decrease equipment downtime

- Increase worker safety

Robots can work around the clock, providing manufacturers with the ability to operate 24/7 and thus significantly increase productivity.

Sustainable Manufacturing

Manufacturing processes often require large amounts of energy and water and can often produce harmful waste and other by-products. Sustainability initiatives are becoming an increasingly important factor. Consumers are becoming more environmentally conscious, and governments continue to implement regulations to reduce carbon emissions and protect the environment. This leads to mitigating the impacts of climate change by insisting on efforts like carbon neutrality and minimizing their carbon footprints.

Companies engaging in sustainable manufacturing aim to reduce waste, conserve resources, and minimize the use of harmful substances. Various renewable energy sources are being considered. Also, adopting circular economy principles and implementing eco-friendly production processes are being considered.

Servitization

Servitization is a business model that involves moving from selling products to providing services. In the manufacturing industry, servitization involves offering customers after-sales services—such as maintenance, repair, and upgrades. This model can help manufacturers build stronger customer relationships, increase customer loyalty, and generate recurring revenue lines.

This concept also enables manufacturers to differentiate themselves from competitors by offering value-added services that enhance the customer experience. Furthermore, it is helping manufacturers to gain valuable insights into their customers’ needs, tastes, buying behavior, and their preferences. This is considered as a valuable input to the product development team and thus can help to improve customer satisfaction.

Reshoring

Reshoring is the process of bringing manufacturing operations back to their home country from overseas locations. This trend has gained momentum recently due to labor shortages, supply chain disruptions, geopolitical risks, and rising labor costs in overseas locations.

Reshoring can provide several benefits to manufacturing companies. Benefits are varied, and to name a few, it helps to reduce transportation costs, improve quality control, and increase flexibility.

Additionally, reshoring helps to create new jobs and support local economies.

Extended Reality

Extended Reality (XR) refers to technologies that merge the physical and digital worlds, for example, Virtual Reality (VR) and Augmented Reality (AR). One of the chief benefits of XR is its ability to improve employee training and education and address worker skills gaps.

XR technologies help manufacturers create immersive training simulations that help employees learn new skills and procedures in a controlled/simulated environment.

This helps to get real-time information for their workers and thus helps to achieve more productivity with increased accuracy.

XR can provide consumers with an enhanced customer experience by providing virtual product demonstrations and visualizations. With this, manufacturers can design and develop better products for their customers because, with XR, the designers can visualize and test products in a virtual environment before they are mass-produced and sent to market.

Advanced Materials

As manufacturing processes have advanced, so too have manufacturing materials. Advanced materials like composites, ceramics, and nanomaterials are becoming the industry norm, as these materials offer increased strength and durability and improved thermal properties against traditional raw materials. Advanced materials have various applications, including aerospace, automotive, and healthcare manufacturing. Composite materials are helping manufacturers to produce lightweight and fuel-efficient aircraft, while nanomaterials are being used to develop new medical treatments.

Digital Twins

A digital twin is a virtual replica of a physical object or system equipped with sensors and connected to the internet. A digital twin also simulates scenarios and tests configurations before implementing them.

A digital twin can collect data and provide real-time performance insights. In smart factories, digital twins are used to monitor and optimize the performance of manufacturing processes, machines, and equipment.

By collecting sensor data from manufacturing equipment, digital twins can detect anomalies, identify potential problems, improve forecasting capabilities, and provide insights into optimizing production processes.

Digital twins have become an increasingly popular concept in the world of smart manufacturing.

Comments

No comments yet. Be the first to comment!