Lightning Protection in Buildings

Necessity of lightning protection system:

- Lightning is one of nature’s most powerful & destructive phenomena.

- It contains a huge amount of energy (several thousands of Amps)

- It is a short duration ( up to 200 µsec ) but is a real cause of damage & destruction

- Primary effect- Buildings damaged, trees blown, personal injuries and even death

- Secondary effect- Transient overvoltage- damage to electronic system

- It can also cause fire, explosion, chemical release or mechanical disruption within or around a bldg.

Lightning Protection System (LPS)

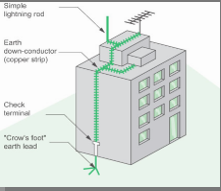

- The lightning rod (Rod is earthed by one or more conductors)

- The lightning rod with taut wires (stretched above structure)

- Lightning conductor with meshed cage/Faraday cage (numerous down conductors & tape symmetrically placed)

Standards:

- BS 6651

- NFPA 780

- BS-EN/IEC 62305

- In Aug. 2008, BS 6651 has been withdrawn

- Now IEC 62305 & NFPA 780 are the recognised standards for LPS

Elements of a Lightning Protection System (LPS)

- Air Termination System (Arrestor)

- Arranged at or along upper points of a roof

- Used to capture lightning current

- Dissipate it harmlessly to earth

- Material- Copper, Aluminium

- It consists of base, air rods & multiple points

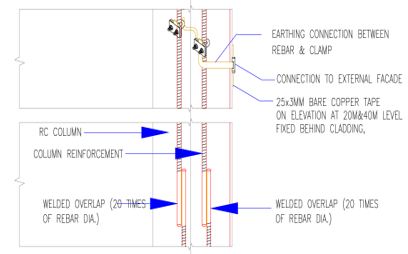

- 25*6 mm Al tape on surface interconnected through clips and clamps (fig. 1 to 3)

- Clamps will ensure a low resistance, corrosion-resistant connection between air termination and down conductors.

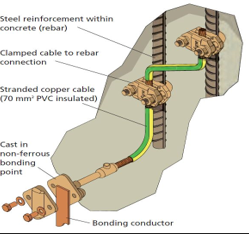

- Down Conductors ( Steel rebar )

- Provides direct route from arrestor to earth

- Greater the no, better the current sharing

- Placed in concrete column (during civil work) or can be bare conductor

- Either copper or steel bars are used

- 2 reinforcement bars of 25 mm dia. Placed in the centre of the column along the periphery

- Rebar to rebar connection-20D to ensure secure connection & proper bonding

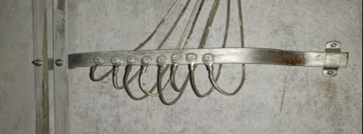

Fig 1 shows Test links- Periodic disconnection & testing of the earth termination system

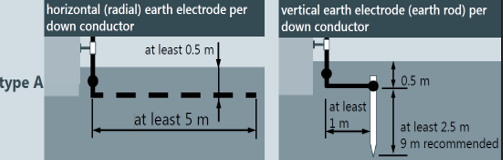

- Earth Termination system ( Earthing )

- Vital for the dispersion of current safely & effectively

- It should have low electrical resistance & good corrosion resistance

- It consists of earth electrodes, plate, mat, pits, Bars, earth points, bonds & clamps

Earth electrode arrangement should be as mentioned below :

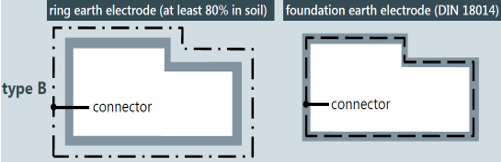

Type A

Type B

- Lightning Equipotential Bonding

- Interconnection of all metallic parts e.g. cable armouring, gas, water piping

- So in the event of lightning, no metallic part is at a different voltage level w.r.t. one another

- Should be near to Main LT / HT Panel & closely connected to earth with short length conductor

Where to provide earth connection?

- Body Earthing

- Neutral grounding ( only at source end – transformer & Diesel generator )

- Earthing for lifts

Non-conventional methods of earthing are pile earthing (cost-saving) & Ashlok chemical earthing.

Pile earthing chambers for body earthing.

Comments

No comments yet. Be the first to comment!