Green Hydrogen: Potential and Challenges Ahead

Green Hydrogen is the name widely given to hydrogen produced by electrolysis - the process of using electricity to split water into its constituent components of hydrogen and oxygen. If the input electricity is renewable, then the resulting hydrogen has a low carbon footprint.

Electrolyzer Technologies for producing Green Hydrogen

There are various types of electrolyzer, but the key component of all technologies is the ‘stack.’ This device consists of a series of electrochemical cells that use catalysis to split the water and a material that is conductive to ions (but not electrons). The stack is then supplied with ultra-pure water (requiring a water purification module) and DC electricity (requiring a transformer and rectifier), and outputs oxygen, hydrogen and heat.

Heat exchangers and radiators extract heat, while equipment purifies hydrogen (removing water and oxygen) and usually vents oxygen.

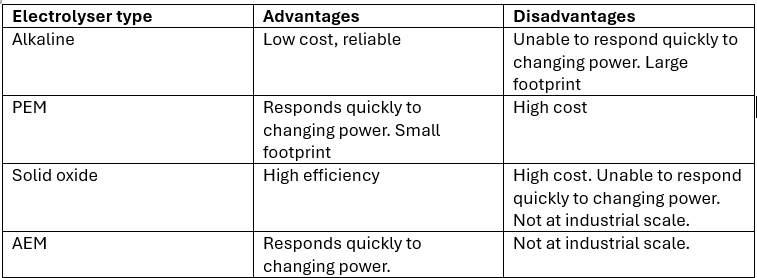

Electrolyzer technologies have the following advantages and disadvantages:

With this in mind, the following technology is most suited to the following markets:

Future of Hydrogen as a Transport Fuel

For over a decade, vehicle companies have been developing hydrogen fuel cell vehicles and funding has been in place from a variety of public bodies for the rollout of Hydrogen Refuelling Stations (HRS), yet this has not led to the anticipated widespread rollout of hydrogen vehicles. Furthermore, companies have recently announced the closure of several HRS.

So, is this the end of the road for hydrogen vehicles?

Increase in the global sales of Hydrogen fuel

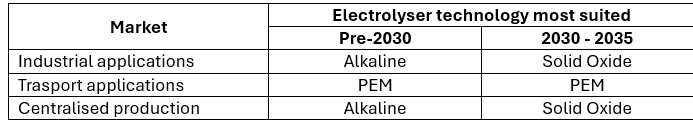

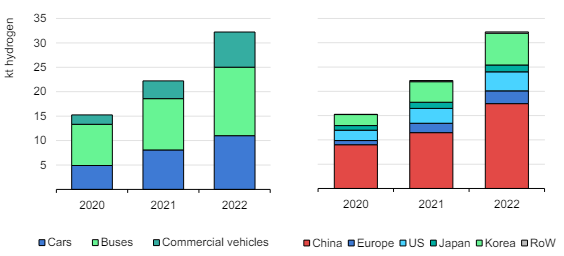

Firstly, while the West has had little activity on hydrogen as a transport fuel, this is not the case in the East. Globally, fuel sales have risen 45% year on year, with commercial vehicles seeing the largest rise.

Figure 1. Increase in hydrogen transport consumption, split by vehicle type and country (from IEA Global Hydrogen Review 2023)

Investing in Large Hydrogen Vehicles

The wrong vehicles and HRS were initially produced for hydrogen. Hydrogen is competing against battery vehicles and generally (excluding niche markets), batteries are better in smaller vehicles (scooters, bikes etc), while fuel cells are the better technology in larger vehicles (ships, trains etc).

It is not as clear-cut in the car/bus scale, but it is believed that the crossover point is between the scales of cars and buses, with cars being better as battery vehicles and buses being better as hydrogen vehicles. Unfortunately, vehicle manufacturers and public bodies made the wrong call and chased hydrogen cars for a decade, with both now being reticent to invest in the technology for mass rollout of large hydrogen vehicles and HRS.

So what is the future? Eventually, hydrogen will dominate large low-carbon vehicles (buses, trains, construction equipment); however, the mistakes of the past mean this is likely not to occur until mid-2030s.

Frequently Asked Questions Answered by Kris Hyde

1. What are the problems with producing green hydrogen?

The widespread rollout of green hydrogen has many impediments. Most analysts would simply state that electrolyzer cost is the biggest barrier, which in many ways is true, but the statement hides some subtleties.

It is possible if one calculates the Cap-Ex and Op-Ex required to reach parity with grey hydrogen (hydrogen produced from natural gas).

However, this is only if the renewable electricity input is extremely low priced and electrolyser prices are less than half of their present value. Given that it is possible to reach these low electricity generation costs in certain locations, the focus is therefore on the electrolyzer price.

However, there are some points to consider here:

Cost of the Electrolysis for Hydrogen Production

Parity with grey hydrogen may simply be an unrealistic target. Natural gas is just about the cheapest form of energy for good reason: you literally dig a hole and energy flows out ready to use. Nature has kindly created it and pressurised it for us.

Conversely hydrogen via electrolysis needs creating and pressurising to use. It will simply be more expensive to have the acknowledged benefits of zero carbon - Probably twice as expensive with it being phased in over a decade. Impossible to accept? Consider that (for example) UK wholesale natural gas spot price rose 5 fold in 8 months in 2022 with no forewarning.

Mass Production of Electrolyzers

Most people advise that mass production of electrolyzers is the best way of reducing cost, and investors applaud manufacturers opening ‘giga-factories.’ However, electrolyzers are not mass-produced. Most of these factories are presently empty spaces. Not only are they presently sold in numbers too small, but the scale of projects (and hence electrolyzers) is rapidly growing. Imagine setting up a factory to produce motorbikes, then the following year changing to make 2 seater sports cars, then the following year saloons, then the following year a people carriers… Its not possible to mass produce until the market matures and the scale of modules becomes clear.

Inflation

We have spent 2 years living in a world with strong inflation. Everyone accepts that the cost of everything has risen substantially in this time. Unless you manufacture electrolyzers, where investors still expect you to hit cost targets published 5 years ago. This is unrealistic.

Availability of Renewable Energy

While it is possible to produce renewable energy for a few dollars per MWh, as an electrolyzer owner, you can’t buy it at this price. You buy at the wholesale price, as why would the RE owner sell to you when they can achieve several times more income selling to the grid?

Comments

No comments yet. Be the first to comment!