Gearbox Fundamentals: Types, Uses, and Care

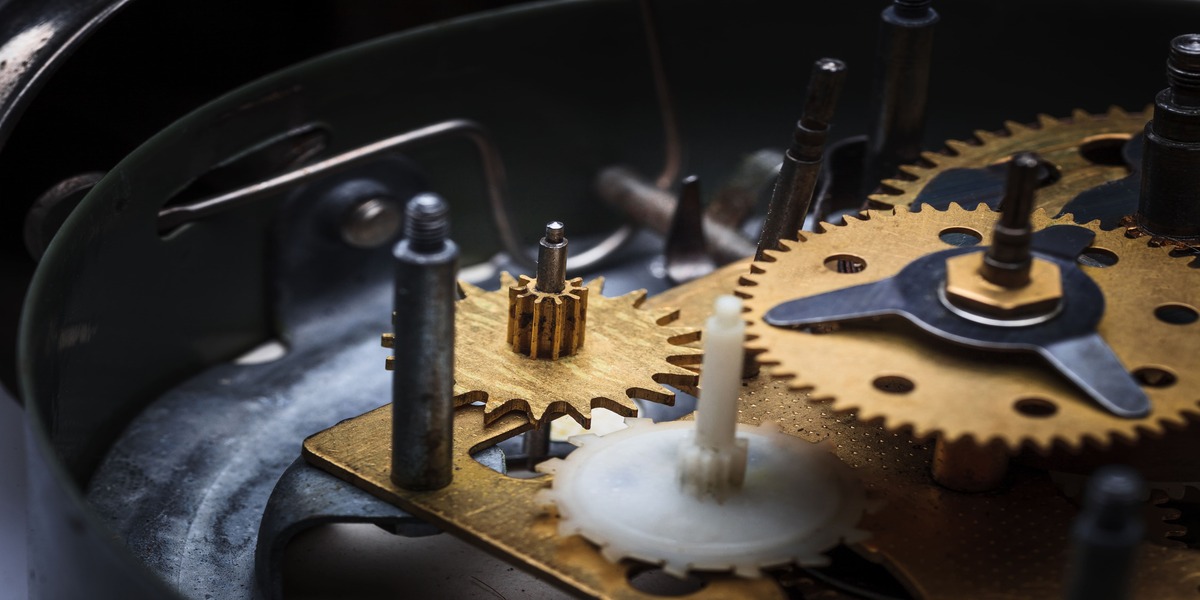

A gearbox is a collection of mechanical components that deliver maximum power from an engine by managing a series of gear ratios that, in turn, operate a transmission. These components include:

- Gear selector

- Fork

- Dogteeth

- Gear set

The gearbox, with its primary function of increasing or reducing speed, plays a crucial role in managing an engine's power output. This results in a proportional change in torque output, where an enclosed drive as a speed reducer (speed output is less than speed input) will increase torque output, and vice versa.

Types of Gear Box

-

Helical gearbox

- Coaxial helical inline gearbox

- Skew bevel helical gearbox

- Worm reduction gearboxes

- Sliding mesh type gear box

Applications of Gearbox

Gears are required to keep the engine at rotational speeds, which creates a desirable amount of power across a wide range of road speeds. Generally, the faster an engine turns, the more fuel it consumes and the more power it makes. Engines are also only capable of rotating to a maximum speed.

The various areas where the gearbox is used are:

- Marine

- Industrial equipment

- Steel Plant

- Railway

- Power Plants

- Cooling Towers

- Automobiles & etc.

Reasons for Gearbox Failure

Gearbox failure can causes a complete machinery breakdown, expensive both in their subsequent repair and lost output.

- Inadequate lubrication

- Contamination

- Installation errors

- Overload

- Handling errors

The major causes are inadequate lubrication caused by underfilling, incorrect specification, mixing or incompatibility, incorrect lubrication and intervals, deteriorated grease oil, water contamination, and particular contamination.

Water contamination essentially disables the lubricating properties of the oil & can cause forming of the oil. Water in the oil can result from condensation or falling seals, allowing water to enter.

Overloaded components cause 7% of failures by exceeding design limits for load, speed, or temperature. The greater the overload, the shorter the component life.

The primary symptoms of overload include noise, vibration, and increased temperature.

Metallic chips debris and reduced equipment performance.

Frequently Asked Questions

1. Which materials used to make a gearbox?

The materials used to make gears usually depends on the applications. The gears can be manufactured from either metallic or non-metallic materials. Metallic gears can usually be obtained from steel, cast iron, bronze etc.

A few of the most commonly used materials are EN353, SAE8620H and 20MnCr5. They are arranged according to their strength in descending order. The strength of materials is directly proportional to their cost.

So, if you require a gear for high torque application you go for EN353.

2. How do you maintain a gearbox?

- Keep your gearbox lubricated at all times

- Always keep your gearbox clean

- Ensure proper cooling of your gearbox

- Analyze the vibrations of your gearbox

3. Which bearing is used in gearbox?

- Cylindrical roller bearing

- Spherical roller bearing

- Tapered roller bearing

Comments

No comments yet. Be the first to comment!