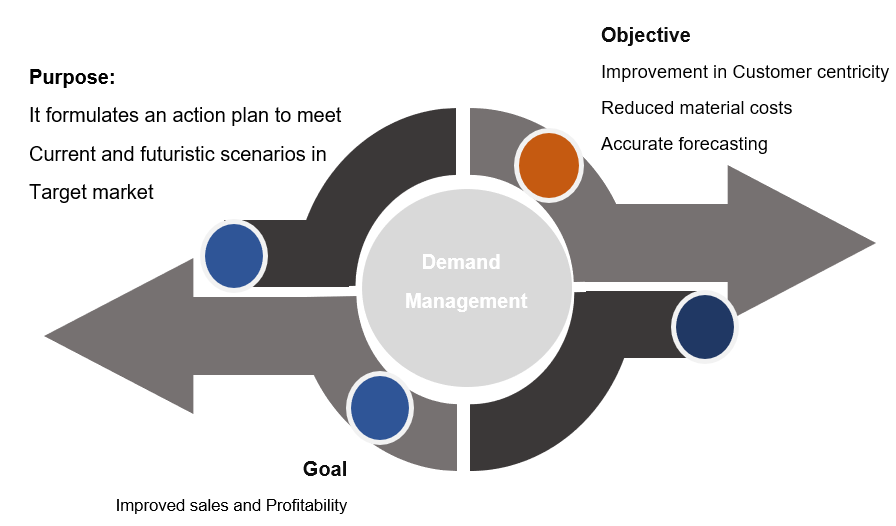

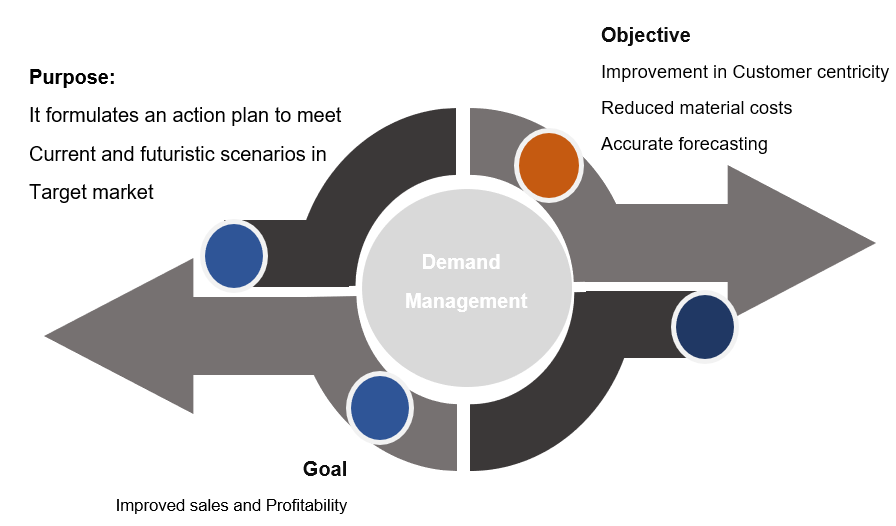

Demand management is a planning methodology that ensures that the demand for something stays the same as the available amount. Organizations use it to forecast and plan how to meet the demand for services and products.

It improves connections between operations and marketing. The result is tighter coordination of strategy, capacity, and customer needs.

Demand management processes help organizations gather valuable insight and agility, and improve the ability to plan and forecast while increasing the visibility into customer demands.

It is far more robust than developing a demand or a sales forecast. Improper demand forecasting results in more supply chain costs and low margins.

Organizations are competing to apply new technologies and analytics to make their supply chains more efficient, reduce inventory, and improve customer satisfaction while improving profitability. This implies the need to have an effective process for demand management.

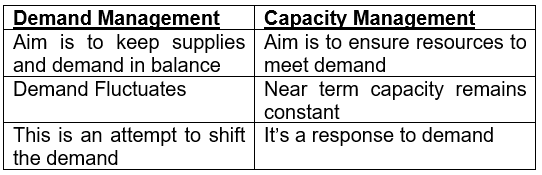

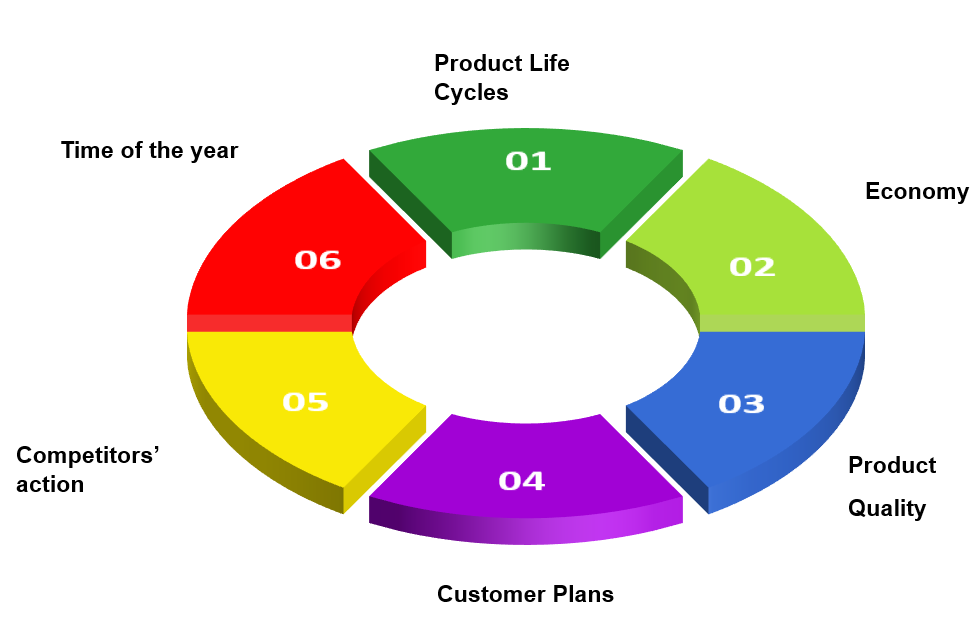

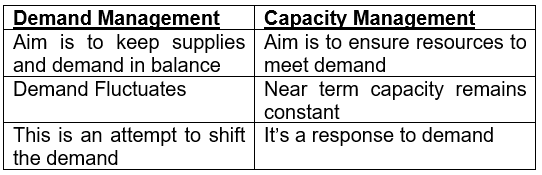

Demand Management and Capacity Management

Demand Management Strategies

Systematic demand management requires high-quality data that teams then analyze continuously with a periodic frequency, depending on the external environment and type of business.

The process includes updating forecasts based on that data to inform strategies.

Today's demand management strategies focus on cost reduction, revenue enhancement, and streamlined operations. Here are some top-demand planning strategies to help enterprises get customers the goods they want and when and where they want them.

Bring demand signals together

To accurately forecast the demand, companies need to understand how many widgets they will sell across multiple sales channels, Griswold said.

Create a holistic understanding

Using the supplier lead time strategically is critical for a successful demand planning.

Demand planners have to understand what the rest of the organization is doing, so that they are not unprepared and have either the wrong kind of inventory or insufficient inventory.

Team up with customers

Many important supply chain strategies rest on communication, including communication with the external supply chain stakeholders.

Closer collaboration with the customers, including asking them to share their ordering plans, can help an organization lower its inventory carrying costs.

Partner with suppliers

A list of top demand planning strategies would not be complete without discussing about the supplier relationships.

Suppliers can offer valuable insights into their requirements and capabilities, such as determining short- or long-term requirements for certain products, developing forecasts, and providing key information about their inventory levels and capacities.

Provide demand planning training

The demand planning process is a complicated and multi-faceted system. There are several contributions made from all over the company.

With so many parts working together in this cross-functional dynamic, it is vital that the companies keep their employees well-versed and trained on the importance of their input.

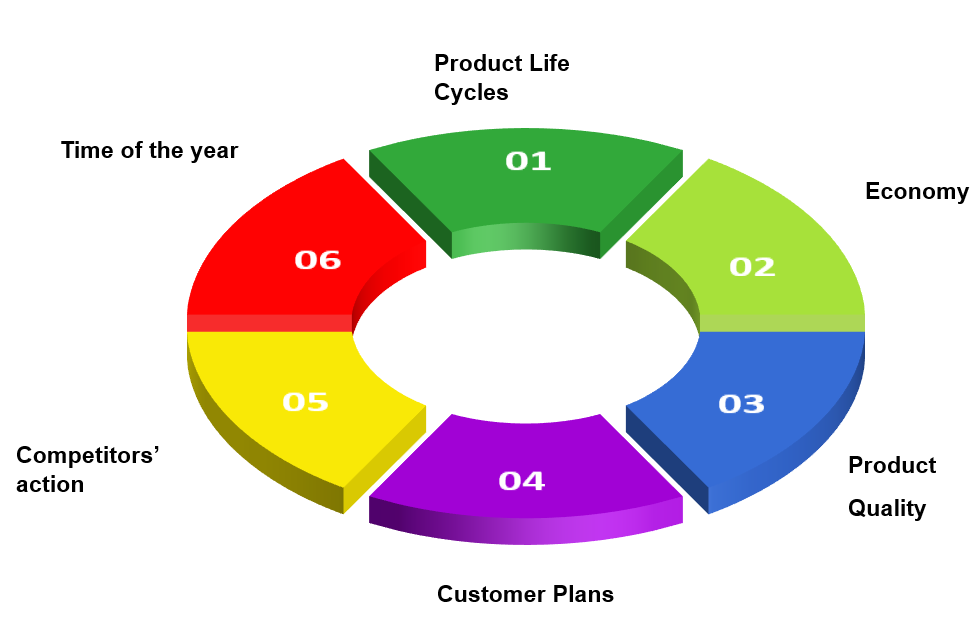

Factors Affecting Demand

This article was contributed by our expert Manoj Yermalkar

Frequently Asked Questions Answered by Manoj Yermalkar

Q1. What are the three most important technologies in the supply chain currently?

- Digital Supply Chain Twins

- IOT and IIOT

- 3D Printing

- Blockchain

Q2. How can we improve customer centricity?

By having four key characteristics, we can make up a customer-centric supply chain:

- Providing Customised value solutions on time

- Meeting uncertain demands of the customers

- Ensuring trustworthy relations

- Focus on innovation

Q3. What are the critical elements of demand planning?

- Sales data by region/location

- Lead times

- Manufacturing times and Inventory Turnover are some of the critical elements

Q4. What forecasting methods are used in supply chains?

Quantitive forecasting

Exponential smoothing

Adaptive Smoothing

Regression analysis

Qualitative research

Market research

Historical analysis

Delphi Method