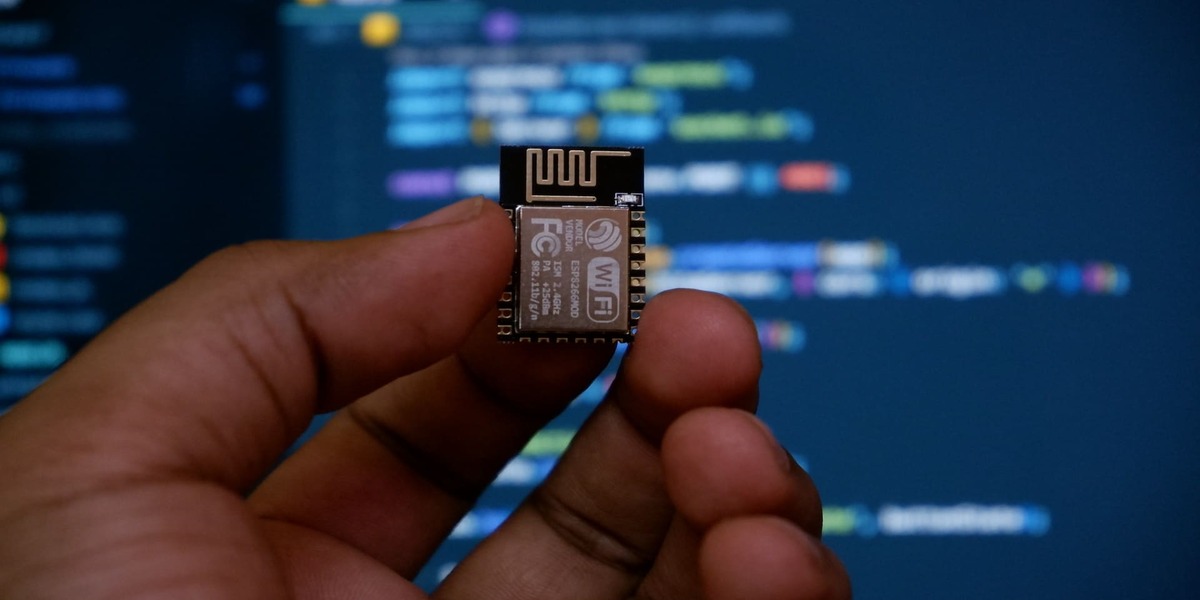

Data Integration And IoT In The Supply Chain

Advancements in real-time data integration in IoT (Internet of Things) environments have significantly improved many aspects of supply chain management. These advancements help companies make more informed decisions, enhance visibility, optimize operations, reduce costs, and drive new revenues.

Technologies in real-time integration, data science, and analytics are now mature, past the “Technology Hype Cycle”, and in production, as you can see in some of the use cases I have highlighted below.

If you combine this with the rapidly evolving advancements in AI, companies will start to realize benefits from predictive modeling in combination with the analytics of current and past events.

We are all aware that data is being generated exponentially:

- 328.77 million terabytes of data are created each day

- This equates to 120 zettabytes per year (1 billion terabytes or 2 to the 70th power of bytes)

- According to the IDC, there will be 41.6 billion IoT devices in the Energy Industry by 2025, generating 79.4 zettabytes of data!

- According to a McKinsey estimate, connected cars create up to 25 gigabytes of data per hour

This article is not intended to take a deep dive into the technology but to look at some key advancements and their respective use cases. This helps validate the technology's maturity and provides thought into further areas of opportunity.

Use Cases of IoT in Supply Chain Management

Edge Computing

IoT devices at the edge of the network are equipped with processing power, enabling them to preprocess data before sending it to central servers. This reduces latency, conserves bandwidth, and allows for faster real-time data integration.

5G Connectivity

The rollout of 5G networks provides high-speed, low-latency connectivity that is crucial for real-time data integration in IoT. This enables devices to communicate and share data faster and more reliably.

Advanced Sensors

IoT devices now feature more advanced sensors, which can collect a broader range of data with higher accuracy. This includes temperature, humidity, location, vibration, and more, enhancing the granularity of real-time information.

Blockchain Technology

Blockchain can be used to securely record and share data in real-time across the supply chain. This ensures data integrity and transparency, reducing the risk of tampering or fraud.

AI and Machine Learning

These technologies are used to analyze the vast amounts of real-time data generated by IoT devices. Predictive analytics, anomaly detection, and machine learning models can help make smarter decisions and optimize supply chain processes.

Integration Platforms

Dedicated IoT integration platforms and middleware solutions have emerged, simplifying the process of connecting various IoT devices and systems. These platforms facilitate real-time data aggregation and transformation.

Cloud Computing

Cloud services, especially edge and fog computing, enable real-time data processing and storage close to the data source. This reduces latency and allows for more responsive decision-making.

Data Streaming Technologies

Technologies like Apache Kafka and MQTT (Message Queuing Telemetry Transport) enable real-time data streaming from IoT devices to data processing systems. This ensures that data is constantly updated and available for analysis.

IoT Standards and Protocols

The development and adoption of standardized IoT protocols and communication standards ensure interoperability between devices and systems, making real-time data integration more seamless.

Supply Chain Visibility Platforms

Specialized supply chain visibility platforms have emerged, offering real-time tracking and monitoring of goods in transit. These platforms integrate with IoT sensors and provide real-time insights into the location and condition of products.

Predictive Maintenance

IoT devices can monitor the condition of machinery and equipment in real time. Predictive maintenance algorithms use this data to predict when maintenance is needed, reducing downtime and improving efficiency.

Environmental Monitoring

IoT sensors can track environmental conditions in real time, which is crucial for industries like food and pharmaceuticals. This ensures that products are stored and transported within specified conditions.

Security

With the increase in IoT devices, security becomes paramount. Advancements in IoT security solutions help protect data and devices from cyber threats, ensuring real-time data integrity. Top of Form

Applications of data integration in IoT in Supply Chain Management

In addition, here are some real-world examples of how advancements in real-time data integration in IoT environments have been applied to Supply Chain Management

Inventory Management

RFID (Radio-Frequency Identification) tags and IoT sensors are used to track inventory in real time. This enables companies to know the exact location and quantity of products in their supply chain at any given moment, reducing the risk of stockouts and overstocking.

Cold Chain Monitoring

IoT sensors are integrated into refrigerated trucks and storage facilities to monitor the temperature and humidity of perishable goods in real time. If conditions deviate from the optimal range, alerts are triggered to prevent spoilage.

Predictive Maintenance

In manufacturing and logistics, IoT sensors on machinery and vehicles collect real-time data on equipment health. Predictive maintenance algorithms analyze this data to schedule maintenance proactively, reducing unplanned downtime.

Route Optimization

IoT devices on vehicles collect data on traffic conditions, weather, and road closures in real time. This data is integrated with route optimization software to adjust delivery routes for efficiency and on-time deliveries dynamically.

Cargo Security

IoT-enabled locks and tamper-evident seals on cargo containers provide real-time alerts if there is any unauthorized access or tampering. This helps prevent theft and ensures cargo security.

Supplier Monitoring

IoT sensors are used to monitor the performance and reliability of suppliers. For example, sensors on manufacturing equipment can provide real-time data on production rates and quality, helping companies manage their suppliers effectively.

Demand Forecasting

Retailers use IoT sensors and smart shelves to monitor real-time product sales. This data is integrated with demand forecasting algorithms to adjust inventory levels and optimize restocking.

Environmental Compliance

Industries like pharmaceuticals and food use IoT sensors to monitor temperature, humidity, and other environmental factors during transportation. Real-time data ensures compliance with regulatory requirements.

Cross-Docking Optimization

IoT devices in warehouses track the arrival of goods and integrate this information with inventory levels and order data in real time. This enables more efficient cross-docking operations, reducing storage costs.

Energy Efficiency

IoT sensors and smart meters in distribution centers and manufacturing facilities collect real-time data on energy consumption. This information is used to identify opportunities for energy savings and reduce operational costs.

Quality Control

IoT sensors in production lines continuously monitor product quality. Real-time data analysis can detect defects early in manufacturing, reducing waste and ensuring product quality.

Customer Experience

Real-time tracking and monitoring of shipments via IoT-connected devices allow customers to receive updates on the status and location of their orders. This improves the overall customer experience and reduces inquiries to customer support.

In summary, advancements in real-time data integration in IoT environments have revolutionized supply chain management by providing greater visibility, efficiency, and responsiveness. These technologies enable companies to make data-driven decisions, optimize processes, and ultimately enhance customer satisfaction while reducing costs and risks.

Comments

No comments yet. Be the first to comment!