A Sustainable Way Towards Sustainability

Sustainability is a topic that is widely discussed across various industries to achieve the climate change target. But it takes time for several stakeholders to agree on the right set of actions to make meaningful progress.

Worldwide inequity in human and economic development makes universal progress on sustainability a daunting challenge before either side even sits across the table. As the developed and the developing countries prioritize differently, they both raise questions regarding the need for steps to be taken to achieve the sustainability goal. Meanwhile, the fluctuations in the climatic events in various parts of the world make a growing number of these regions less habitable.

The progress in sustainability goals of a nation is determined by two major factors- national agenda and citizen activism.

Steps Taken at National Level

The authorities that present the sustainability guidelines and every industry player and government should focus on progressing global sustainability. Companies undergoing digital transformation or driving advanced manufacturing (Industry 4.0 and 5.0) also contribute to sustainability.

Steps taken at Organizational Level

At the enterprise level, the understanding of sustainability varies across each industry or organization, resulting in different methods. A well-thought approach to sustainability starts with a holistic audit of the present and the proposed future supply chains down to every element's source (land, water, or air).

Key areas of Sustainability in Industries

Some of the key areas of sustainability that most industries should focus are the following:

Materials sourcing/consumption and reuse/recyclability

Materials sourcing and consumption refer to the type, quantity and energy-efficient utilization of raw materials to make end products for various markets and customers. Choice of material has a huge impact here, and deep innovation is required to ensure that the materials that are most difficult and environmentally demanding to source (or extract or refine) are used sparingly if not avoided altogether.

Per unit resource efficiency

Per unit resource efficiency refers to getting the most of each unit of resource (material or energy) utilized in making products, using them over their lifecycle or while delivering market-relevant services. An example here is the work being done to improve fuel efficiency and per-unit energy use in various industries.

Overall cycle impact of alternatives

This means that each alternative being pursued (as opposed to present materials or methods) should be evaluated for overall sustainability benefits over its entire lifecycle (from ground to the air).

One of the challenges here is some companies fall into the trap of narrowly defining sustainability within their own channel of influence without looking at how their actions impact other elements in the supply chain beyond their scope of influence. This can lead to suboptimal approaches to sustainability, from an overall perspective.

Steps Taken by Consumers

Even consumer behavior can make a sizable impact. Something as simple as reducing your driving speed by 5-10 miles per hour can not only improve fuel economy (and reduce operating costs of a vehicle) but contribute to reduction of greenhouse gas emissions. Elimination and/or reuse of plastic bags is another simple but effective step. Every major progress towards sustainability starts with small steps like these.

Ways Forward

Instead of endless debates about sustainability, real progress can be achieved by the following approach, if followed at all - individual, organizational, industry and national – levels. Ultimately, climate change knows no boundaries and we all share just one planet!

• Define sustainability ‘holistically’ for each development goal

• Develop industry (or other stakeholder) consensus for each sustainability definition

• Deliver what matters under a supportive framework

This article was contributed by our expert Raman Venkatesh

Frequently Asked Questions Answered by Raman Venkatesh

Q1. What are some of the carbon-intensive industries?

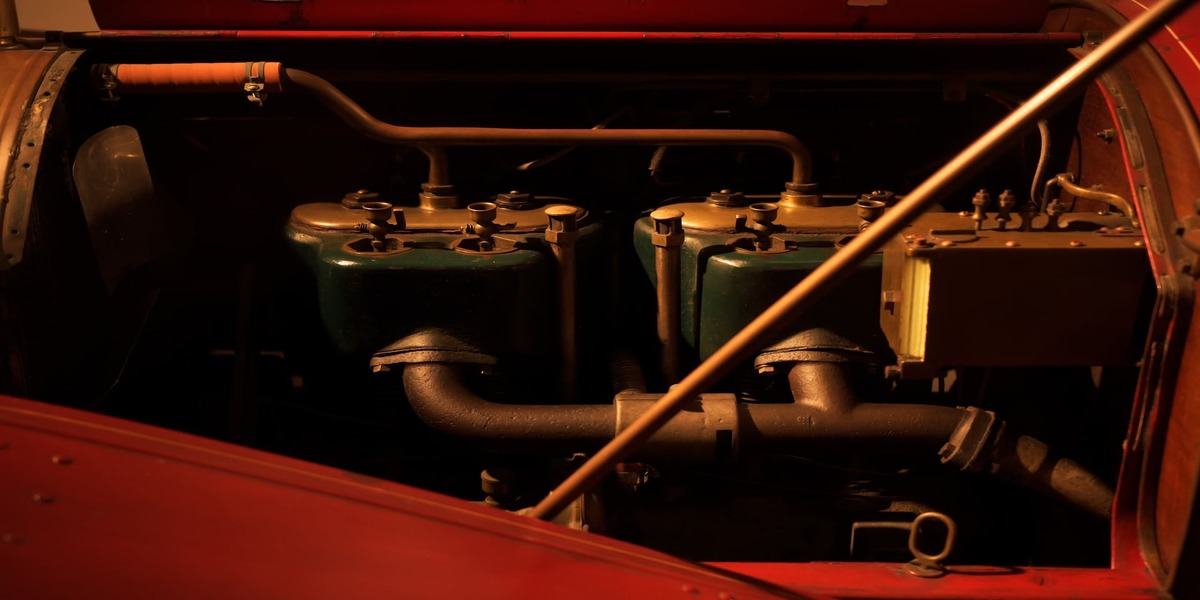

Transportation (mainly commercial, including land and sea-based vehicles) and heavy industrial machinery and infrastructure are carbon-intensive. The challenge in these industries is that the entire lifecycle (from raw materials to production to use and final disposal) is carbon-intensive because they heavily depend on fossil fuels.

These are some of the most fundamental industries for human advancement and global societal progress. So, carbon intensity should be considered on a comparable equivalence basis regarding the benefits these industries provide to society and human progress. We should look at carbon intensity not individually but on a lifecycle basis.

Q2. What are the key areas of sustainability that industries should focus on?

Some of the key areas of sustainability that most industries should focus on are the following:

Materials sourcing/consumption and reuse/recyclability

Materials sourcing and consumption refer to raw materials' type, quantity, and energy-efficient utilization to make end products for various markets and customers. Choice of material has a huge impact here, and deep innovation is required to ensure that the most difficult and environmentally demanding materials to source (or extract or refine) are used sparingly, if not avoided altogether.

Per unit resource efficiency

Per unit resource efficiency refers to getting the most of each unit of resource (material or energy) utilized in making products, using them over their lifecycle, or delivering market-relevant services. An example is the work done to improve fuel efficiency and per-unit energy use in various industries.

Overall Cycle Impact of Alternatives

The third area I mentioned above is overall cycle impact, which means that each alternative being pursued (as opposed to present materials or methods) should be evaluated for overall sustainability benefits over its entire lifecycle (from the ground to the air).

One of the challenges here is that some companies fall into the trap of narrowly defining sustainability within their channel of influence without looking at how their actions impact other elements in the supply chain beyond their scope of influence. This can lead to suboptimal approaches to sustainability from an overall perspective.

Q3. What are the factors affecting sustainable consumption behavior?

One big factor is awareness. Another large one is cost competitiveness. While the awareness factor is being addressed due to global focus and focused communication, the cost competitiveness factor remains challenging. Many sustainable alternatives are more expensive than their conventional counterparts. This is partly due to the scale effect. The sustainable options are early in their market entry and are often 1/10th or 1/100th the scale of established conventional solutions. This will get addressed over time. A relevant example here is solar power.

From 10 years ago, when solar was far more expensive than conventional grid power, today, the cost of solar in many parts of the world has achieved grid parity even without government subsidies. Massive performance and efficiency improvements in solar panel technology drove this. Therefore, the cost competitiveness factor will mitigate in due course, aided in the interim period by government subsidies to drive sustainable consumption behavior.

Q4. What makes Industry 5.0 different from the previous industrial revolution?

Industry 5.0 is "digital first" in its conception, design, and execution with deeply embedded self-learning and self-healing capabilities (powered by AI/ML). Compared to Industry 3.0 and even Industry 4.0, Industry 5.0 looks at the entire industrial activity through the lens of digitally-native products, processes, and solutions with a strongly reinforced self-improvement cycle.

This makes this revolution fundamentally different from the earlier industrial revolutions and transformative for many industries. Industry 5.0 will also deliver the true potential of sustainable manufacturing by pushing the envelope towards 'zero' discharge (or waste) in many industries. There are some concerns about Industry 5.0 significantly reducing the need for human labor. While some of those are valid, Industry 5.0 does offer the potential for improving the quality of jobs to focus on keeping the systems in peak condition rather than routine production-oriented activities.

Comments

No comments yet. Be the first to comment!